Pressure reactors play a vital role in lab-scale and industrial syntheses alike by enabling reactions to be carried out at extremely high-pressures. In this blog post, we explore the basics of how pressure reactors work and the advantages they offer in chemical processing.

What are High-Pressure Reactors?

A pressure vessel is any container designed to hold its contents at higher than atmospheric pressure. Pressure vessels vary tremendously in construction and purpose – from simple mass-produced examples such as aerosol deodorant canisters to high-spec applications such as nuclear reactors and aeroplane fuselages.

In chemistry, purpose-built pressure vessels are used as high-pressure reactors. These are sturdy reaction vessels designed to hold their contents at high pressure while they undergo chemical reactions.

High-pressure reactors must withstand longitudinal, and hoop stresses exerted by internal pressure and provide an inert inner surface to prevent corrosion or contamination. Therefore, the choice of material used to construct high-pressure reactors is critical.

At the lower end of the pressure scale (in the region of 5 bar), glass is preferred since it allows direct observation of the contents of the pressure reactor. However, higher pressures require more robust materials. Stainless steel is a popular choice for constructing pressure vessels rated to around 200 bar. In contrast, even higher pressures (in the region of a few thousand of bars) can be achieved using pressure vessels made from alloys such as Hastelloy or Inconel, both of which offer extremely high strength and excellent resistance to corrosion and oxidation.

Applications of High-Pressure Reactors

Pressure is one of the most important process variables in chemistry, and carrying out reactions in pressure reactors can provide many advantages.1,2

- At high pressure, solvents can be heated to higher temperatures before evaporating. This enables reactions to be carried out at higher temperatures (and therefore more quickly) than at atmospheric pressure.

- Increasing pressure can directly increase the reaction rate, especially for gases, by reducing reactant volume and thus increasing concentration and collision frequency.

- Increasing pressure pushes chemical equilibrium towards the side of the reaction with fewer moles of gas. Depending on the stoichiometry of a reaction, pressure reactors can play a crucial role in increasing yield.

As a result, pressure reactors are crucial in various chemical applications, including hydrogenations and other gas phase reactions, homogeneous and heterogeneous catalysis, corrosion testing, supercriticality studies, and hydrothermal syntheses.

How is Pressure Increased in a High-Pressure Reactor?

There are many ways to increase the pressure inside a pressure reactor. Often, increasing pressure is a simple matter of heating a sealed pressure vessel: temperature and pressure increase in tandem (and the two variables typically have similar effects on reaction kinetics). Reactor pressure is also often increased by the reaction occurring inside it – in these cases, agitation can accelerate the increase in pressure.

In cases where heating is inappropriate and the reaction doesn’t generate sufficient pressure, pressure reactors can be manually pressurized using a pressurized gas source such as a compressor or a pre-compressed canister of inert gas.

Regardless of the source of the internal pressure, pressure reactors rely on pressure relief valves to safely maintain or limit it.

Pressure reactors in convenient standard

or fully customised configurations.

From benchtop to plant scale

Asynt Pressure Reactors

Asynt manufactures a full range of pressure reactors in single– and multi-position formats. As well as a core range of convenient standard configurations, we provide fully customized solutions to suit any specifications from benchtop to pilot scale.

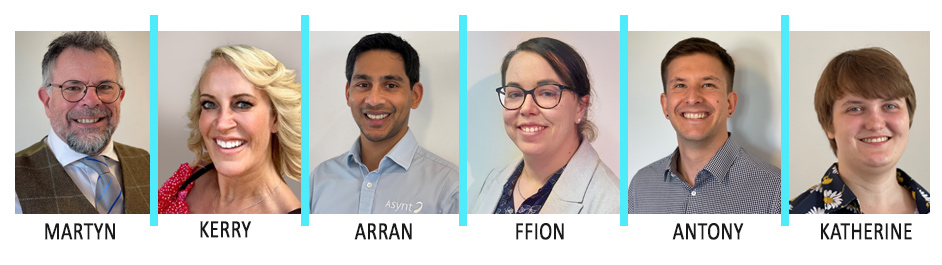

To find out more about Asynt pressure reactors, contact us today – or find out more about our team of experts that design the range:

References and Further Reading

- Chen, B., Hoffmann, R. & Cammi, R. The Effect of Pressure on Organic Reactions in Fluids—a New Theoretical Perspective. Angewandte Chemie International Edition 56, 11126–11142 (2017).

- SITNFlash. high-pressure Chemistry. Science in the News https://sitn.hms.harvard.edu/flash/2014/high-pressure-chemistry/ (2014).

- Asynt Pressure Reactor Overview. Asynt short brochure