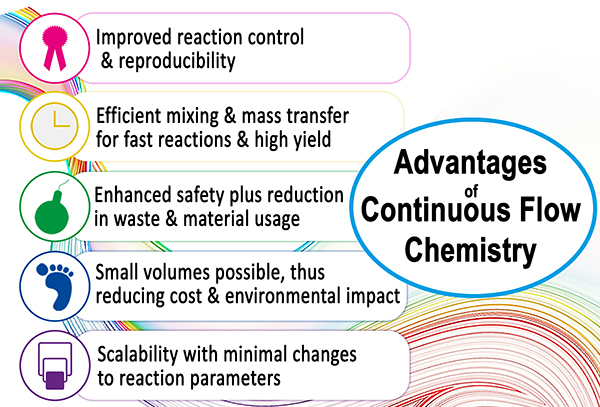

Flow chemistry represents a paradigm shift on the lab bench. It’s a novel alternative to batch processing which is comparatively static, providing limited consistency and scalability. By contrast, flow chemistry is extremely efficient, precise, versatile, cost-effective, and more. It enables quick reactions with more precise controls, which can be easily scaled up for industrial processing. At the heart of this revolution are advanced instruments like the continuous stirred tank reactor (CSTR). The CSTR is a marvel when it comes to efficiency, precision, and scalability in chemical processes. Let’s look further at Flow Chemistry using CSTRs…

Efficiency and Precision in Chemical Reactions

The essence of flow chemistry lies in its continuous flow. CSTRs, in particular, are reactors designed to maintain a steady state, ensuring that the amount of time a reactant spends inside, known as residence times, is consistent. This precise control over reaction times and temperature-controlled environments ensures that chemical reactions achieve optimal reaction rates.

Furthermore, the continuous flow ensures that reactions are not limited by reactor volumes, as seen in traditional batch reactors. This leads to improved yield, purity, and significantly reduced wastage. With CSTRs, the chemical process is streamlined, ensuring consistent and reliable results across various reactions. CSTRs offer multiple efficiency benefits:

- Uninterrupted Functioning: Unlike batch reactors, a CSTR operates without breaks, ensuring a consistent flow of the reaction mixture. This leads to optimal resource utilisation and potentially higher product yields.

- Uniform Product Quality: The continuous nature of a CSTR ensures a stable product quality, eliminating the inconsistencies seen in batch reactors from one batch to another.

- Superior Heat Management: CSTRs boast enhanced heat transfer capabilities compared to batch reactors. This facilitates efficient heat removal from the reaction mixture, averting excessive heat and bolstering reaction efficiency.

- Enhanced Precision: CSTRs offer a higher degree of control than batch reactors, leading to more consistent and dependable outcomes. Factors like reactant and catalyst flow rates can be fine-tuned to perfect the reaction environment.

Adaptable Scale: Depending on production needs, CSTRs can be effortlessly scaled up or down, making them a versatile option for industrial scenarios.

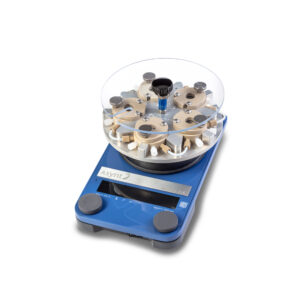

|

|

| fReactor Classic 5 x Continuous Stirred Tank Reactors (CSTR) of 1.8 mL volume each Find out more |

fReactor MAXI 5 x Continuous Stirred Tank Reactors (CSTR) of 7.5 mL volume each Find out more |

Versatility and Scalability of Flow Chemistry with CSTRs

One of the standout features of CSTRs is their versatility. These reactors can accommodate a plethora of flow reactions, from simple to complex, making them indispensable in academic and industrial settings. Their design allows for the seamless integration of different chemical reactors, ensuring that researchers and industries can explore myriad applications.

Moreover, the scalability of CSTRs is commendable. The transition is seamless whether it’s a single CSTR for small-scale laboratory experiments or a series of reactors for large-scale industrial production. This adaptability ensures that flow chemistry remains accessible and practical for diverse purposes, from niche research to mass production.

Innovation and Advancements in Flow Chemistry Technology

The world of flow chemistry is ever-evolving, with CSTRs at its vanguard. The continuous stirred tank reactor CSTR has seen enhancements in its design, ensuring that the time in the reactor is optimised for each specific reaction. There are a wide range of options and accessories to complement any basic setup and these, alongside technological leaps, contribute to the progress of flow chemistry and position it as a forefront technology, indispensable for researchers, scientists, and industries.

Interested in Flow Chemistry Solutions?

At Asynt, we recognise the transformative power of flow chemistry and the pivotal role CSTRs play in its success. We are committed to driving innovation in this field, ensuring that researchers and industries have access to the best tools and technologies.

For those keen to delve deeper into the world of flow chemistry and explore our range of accessible products, we invite you to explore our solutions. Together, let’s shape the future of chemical processes, one reaction at a time.

If you’d like any further information about Flow Chemistry, the fReactor platform, or using CSTRS, please don’t hesitate to contact us. You’re welcome to click the LIVE CHAT box at the bottom right of your screen, complete the short form below to email us, or telephone +44 (0)1638 781709 and ask for one of our technical sales team!

If you’d like any further information about Flow Chemistry, the fReactor platform, or using CSTRS, please don’t hesitate to contact us. You’re welcome to click the LIVE CHAT box at the bottom right of your screen, complete the short form below to email us, or telephone +44 (0)1638 781709 and ask for one of our technical sales team!