DrySyn Sustainability Report: DrySyn Multi systems allow up to 3 reactions to be carried out simultaneously using the same hotplate. Should the efficiency be unaffected, DrySyn would therefore be ideal to reduce the number of hotplates used and reduce energy usage within the lab. This was tested by the University of Liverpool.

DrySyn Comparison of Yields

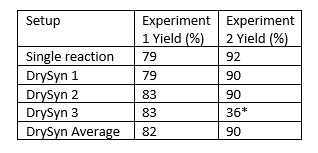

Experiment 1 was an amine synthesis with water as the solvent, and a 90-minute duration of reflux. This was carried out both with a standard competitor heating block to individually heat one flask, and a DrySyn Multi set-up that ran three flasks simultaneously. Meanwhile, experiment 2 was a reduction of 3-nitroacetophenone that took only 20 minutes. The yields of each are recorded in Table 1.

Table 1: The yields of each repetition of both experiments. *Outlier was removed from calculation of the average.

As shown in Table 1, the average yield of experiment 1 obtained by the DrySyn was 3% higher than the yield of the competitor heating block. This means that three reactions can be run per hotplate with no decrease in yield. The variation between DrySyn reactions was minimal, with a relative standard deviation of 2.8%. This is ideal for a teaching lab. Experiment 2 showed that there was a 2 % difference in yield, with the single reaction heating block achieving the higher yield. The anomalous result for DrySyn of 36% was due to a spillage during crystallisation and was therefore disregarded from the average. Therefore, the average yield of experiment 2 as achieved with the DrySyn set up was 90 %.

As shown in Table 1, the average yield of experiment 1 obtained by the DrySyn was 3% higher than the yield of the competitor heating block. This means that three reactions can be run per hotplate with no decrease in yield. The variation between DrySyn reactions was minimal, with a relative standard deviation of 2.8%. This is ideal for a teaching lab. Experiment 2 showed that there was a 2 % difference in yield, with the single reaction heating block achieving the higher yield. The anomalous result for DrySyn of 36% was due to a spillage during crystallisation and was therefore disregarded from the average. Therefore, the average yield of experiment 2 as achieved with the DrySyn set up was 90 %.

DrySyn Electrical Consumption

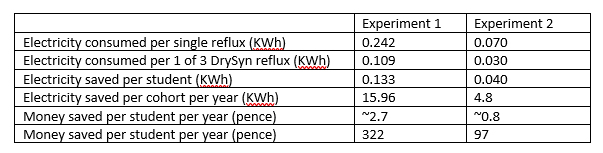

Table 2: The electrical consumption and costs of each experiment

Table 2 shows the electricity usage of both experiments per reaction achieved. In the case of the single flask heating block, this was the electricity used, but for DrySyn, this was a 3rd of the total energy used, as three reactions were achieved simultaneously. The electricity consumed per reaction of experiment 1 was therefore 0.242 KWh for the single heating block, and 0.109 KWh for the DrySyn. In experiment 2, these values were 0.070 KWh and 0.030 KWh for the single heating block and DrySyn KWh respectively. The electricity saved per student was therefore 0.133 KWh for experiment 1, and 0.040 KWh for experiment 2. This shows that performing simultaneous reactions using a DrySyn system saves electricity, with the amount increasing with duration of hotplate use. This means that using DrySyn would save up to 20.8 KWh per 120 student cohort just by these two experiments alone.

Conclusion

The amount of electricity consumed was converted into the cost per 120 student cohort, with results of £3.22 for experiment 1 and £0.97 for experiment 2.

The amount saved by converting to DrySyn for a month of usage during working hours was calculated using the average KWh usage for the experiments.

This gave a result of £3.67 saved a month. This value would be more accurate with greater testing of energy consumption across multiple experiments, however as an indication, this shows that the DrySyn set-up, could save substantially over long periods of time. Furthermore, in case of overnight reactions, the electricity use would be higher than stated, and thus greater savings would be seen. If used with only the experiments explored in the study, the energy usage would be much lower, at approximated 20.76 KWh / annum, which would save only £4.21 a year.

Download this report in full in PDF format HERE or click the image below:

Asynt – Liverpool Étude de cas DrySyn v1.2

Asynt – Liverpool DrySyn-Fallstudie v1.2

You may also be interested in the report made by the University on the CondenSyn Waterless Air Condensers:

You may also be interested in the report made by the University on the CondenSyn Waterless Air Condensers:

If you’d like further information on our benchtop synthesis tools, you can find this HERE or get in touch with us via the LIVE CHAT box at the bottom right of your screen, email [email protected], or call on +44 (0)1638 781709.

If you’d like further information on our benchtop synthesis tools, you can find this HERE or get in touch with us via the LIVE CHAT box at the bottom right of your screen, email [email protected], or call on +44 (0)1638 781709.

Reference: ASY-EV-164