CondenSyn® Sustainability Report: The University of Liverpool tested the yields and reaction times for various experiments across the chemistry department. They used this to determine the performance of the CondenSyn, and the potential water savings through switching to CondenSyn from Liebig condensers.

CondenSyn® Water Savings

Initial testing by the University of Liverpool found that an experienced chemist uses water though Liebig condensers at a flow rate of 100 mL/minute, whilst an inexperienced chemist uses a flow rate of 700 mL/minute. These figures were used to calculate the total water savings across a cohort of 120 students for various experiments in both scenarios.

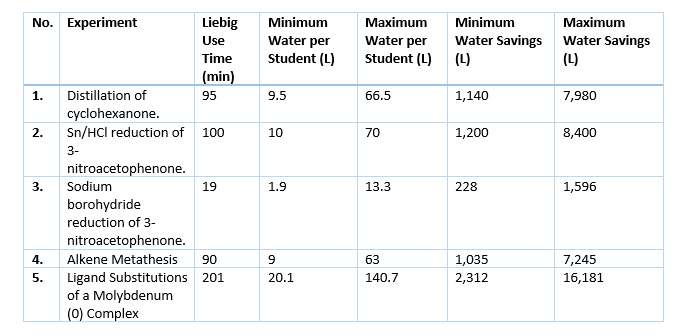

Table 1: Potential water savings across five experiments

As shown in Table 1, the total potential water savings across 5 experiments could range from 5,914 L to 41,402 L. As the first three experiments are for 1st year undergraduates undergoing module CHEM130, it is highly likely these will be carried out with much higher flow rates of up to 700 mL/minute. In these experiments alone, close to 17,976 L of water would be used by a cohort of 120 students. The last two experiments are for 3rd year undergraduates undergoing module CHEM3X5, who would be expected to use a lower flow rate. Ligand substitution of a molybdenum (0) complex, however, is a much longer, more complicated, experiment and uses 20.1 L per student at a minimum, resulting in a 2311 L loss across all 120 students.

As shown in Table 1, the total potential water savings across 5 experiments could range from 5,914 L to 41,402 L. As the first three experiments are for 1st year undergraduates undergoing module CHEM130, it is highly likely these will be carried out with much higher flow rates of up to 700 mL/minute. In these experiments alone, close to 17,976 L of water would be used by a cohort of 120 students. The last two experiments are for 3rd year undergraduates undergoing module CHEM3X5, who would be expected to use a lower flow rate. Ligand substitution of a molybdenum (0) complex, however, is a much longer, more complicated, experiment and uses 20.1 L per student at a minimum, resulting in a 2311 L loss across all 120 students.

At a rate of 0.31 p per L based upon rates quoted by UK water agencies in August 2022, this could save up to £128 just across these experiments. Converting to CondenSyn for the three 1st year undergraduate experiments alone could save £55 per year. CondenSyn would pay back the initial costs of purchase after approximately 9 months of operation during working hours in a 1st year lab. Within the labs of more experienced chemists, the payback time would be longer, with the maximum time being several years.

CondenSyn Performance

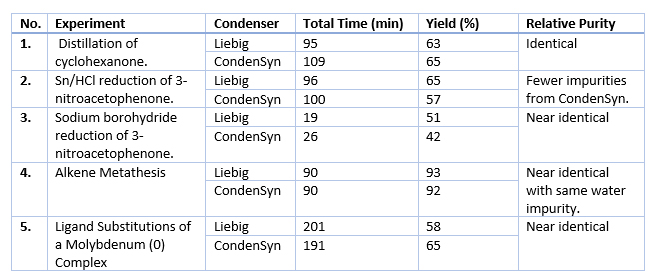

Table 2: Reaction performance comparison between Liebig and CondenSyn condensers

Table 2 shows that while most experiments were faster with the Liebig condenser, the longest time additionally taken using CondenSyn was only 14 minutes, in experiment 1. Experiment 5 showed that in some cases, CondenSyn starts refluxing sooner than the Liebig condenser, leading to a shorter overall time of the experiment. CondenSyn may also save time setting up, as less time needs to be spent on the water supply and tubing.

Table 2 shows that while most experiments were faster with the Liebig condenser, the longest time additionally taken using CondenSyn was only 14 minutes, in experiment 1. Experiment 5 showed that in some cases, CondenSyn starts refluxing sooner than the Liebig condenser, leading to a shorter overall time of the experiment. CondenSyn may also save time setting up, as less time needs to be spent on the water supply and tubing.

The yields between both condensers were quite similar overall. Two of the experiments had negligible differences in yield (experiments 1 and 4), whereas experiments 2 and 3 demonstrated decreases in yield from Liebig to CondenSyn of 8% and 11% respectively. Experiment 5 however showed an increase in yield using CondenSyn of 7%. This may suggest that the optimum condenser may vary from reaction to reaction. Overall, the average yield achieved was only 9% less for CondenSyn, showing that overall, both condensers are relatively equal in terms of achievable yields.

Low boiling solvents

DCM was used as the solvent for experiment 4, which showed very equal yields between results from Liebig condensers and CondenSyn. This shows that solvents with lower boiling points such as DCM with a boiling point of 39.6 ᵒC can be used with the CondenSyn. This does however require careful control of the reaction temperature to prevent solvent breakthrough, and CondenSyn may be less suited to solvents with lower boiling points than DCM. Reflux experiments were carried out using THF, a solvent with a boiling point of 66 ᵒC to investigate further the performance of CondenSyn with low boiling solvents. The lowest recovery was obtained when refluxing at 66 ᵒC and was attributed to incomplete sealing of the PTFE sleeve at the lower temperatures. However, the solvent recovery improved with increasing temperature, and at 26 ᵒC above the boiling point, the solvent loss was negligible. This shows that for THF, a temperature excess of up to 40 % above the boiling point produces acceptable results.

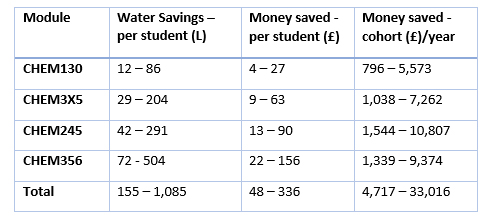

Total monetary savings

Table 3: The total monetary value of the money saved across four chemistry modules, based upon rates quoted by UK water agencies in August 2022

The potential value of water saved across a total of four chemistry modules was estimated using the approximate reaction times, in addition to the two modules where the water saved was determined experimentally. Shown in Table 3, the additional modules CHEM245 and CHEM356 each had large variations in the potential water savings per student. It should be noted however, that whilst CHEM245 had a cohort size of 120 students, the cohort size of CHEM356 was only 60 students. Therefore, for CHEM245, the potential money saved per cohort a year ranges from £1,544 to £10,807 but for CHEM356, the potential money saved ranges from £1,339 to £9,374. As a result, the total potential money saved across all four modules per annum would be £4,717 to £33,016. At the lowest amount, the payback time to cover the cost of 120 CondenSyn would be 4.6 years, however, at the highest water savings, this could be as short as 0.7 years, or 8.4 months.

Left: Alex Rain who has complete his BSc in Chemistry and completed the work around waterless condensers

Right: (L) Stephen Chappell, (C) Lynne Chapman and (R) Stephen Brough winning the LEAF award for the Central Teaching Laboratories

Background information:

The Central Teaching Laboratories and the Department of Chemistry at the University of Liverpool (UK) has published the in-depth study above that reports upon their implementation of Asynt laboratory equipment across multiple undergraduate teaching modules as they strive to meet their primary sustainability goals, reducing waste and to become net zero by 2035.

Driven by the global energy crisis, and the need to address laboratory waste to help fight climate change, the Central Teaching Laboratories chose to invest in Asynt DrySyn heating blocks and CondenSyn waterless condensers. This was thanks to a successful sustainability bid from Dr Stephen Brough and Lynne Chapman. Testing of these against traditional heating blocks and condensers by student Alexander Rain in undergraduate experiments showed tremendous improvement to the sustainability of the department.

Download this report in full in PDF format here: Asynt – Liverpool CondenSyn Sustainability Report

Asynt – Liverpool Étude de cas CondenSyn v1.2

Asynt – Liverpool CondenSyn Fallstudie v1.2

Read the DrySyn Sustainability Report next: https://www.asynt.com/evaluations/drysyn-sustainability-report/

Reference: ASY-EV-163