Safety is paramount when conducting chemical reactions under pressurised conditions. Yes, your department ordered a fabulous new pressure reactor that you’ve been itching to get your hands on – but how does the specification meet your chemistry needs? The setup might have been modified. Someone could have dropped the pressure reactor and bent an inlet/outlet valve. Whether working with a small single-cell pressure reactor or a more complex multi-cell pressure reactor system, it’s essential to put user safety first and follow some simple steps for pressure safety in your laboratory.

Laboratory safety isn’t just about you, though. Improper preparation can cause potential hazards that could be disastrous if left unchecked. Make sure you take the time to carefully prepare your pressure reactor and lab safety equipment, as even minor problems can escalate incredibly quickly when working under pressure. At the end of the day, you’re responsible for yourself – but you’re also accountable for your impact on those in your general environs.

The ten simple steps for safety when working with pressure reactors included below should never replace any existing guidance in your laboratory, nor common sense. They are intended as key points to check before you put yourself under unnecessary pressure:

- Refer to existing in-house guidance: This would include sources such as chemical laboratory safety signs and warning symbols posted locally, but users should ensure they are aware of all current and applicable laboratory safety rules. Are there any particular safety precautions in your pharma laboratory that you need to refresh yourself on? Don’t assume that nothing has changed.

- Construction limitations: Familiarise yourself with the chemical properties of your pressure reactor material. Is the metal chemically resistant enough to cope with anything you’ll be using in your reaction? Stainless steel pressure reactors are common, though chemical resistance varies from grade-to-grade.

- Links in the structure: Don’t forget to ensure that the o-ring on the vessel and any joints where further apparatus is connected to the head are all sound. You should also verify if any o-ring is made of a suitable material for your work.

- Vessel capacity: One of the most frequently overlooked hazards of working with pressure reactors is caused by operators overfilling the vessel. It must never be filled to more than three quarters of the free space, and in some situations, this must be reduced even further. Remember: when a liquid is heated in a closed vessel without capacity for the expanded volume, dangerous pressures can suddenly develop. This is particularly true of water and water solutions, so users must be aware that these can increase to as much as three times their original volume when heated to the critical point (374 °C). At temperatures up to 200 °C the increase in volume is relatively small but after this it expands dramatically.

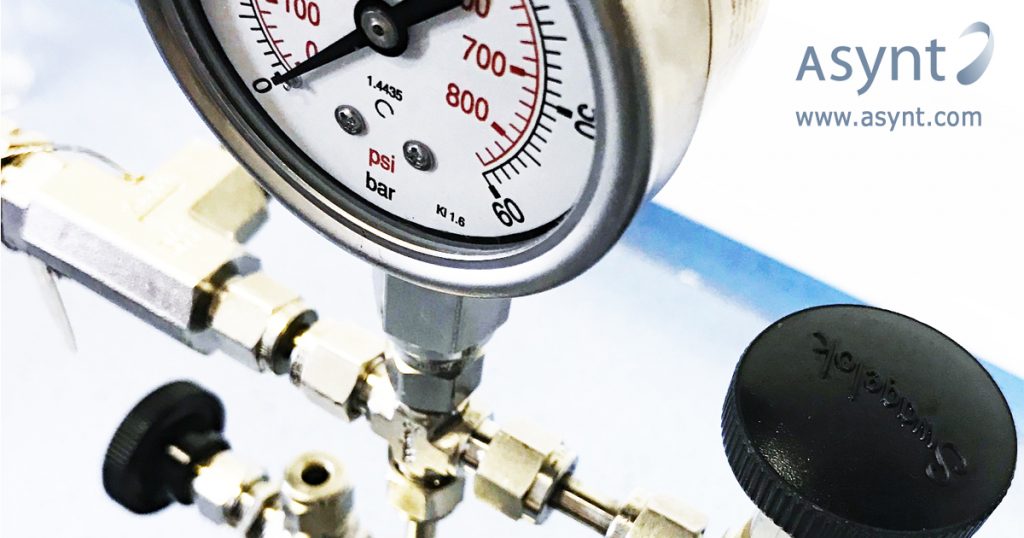

- Temperature and pressure rating: Users must check that the pressure vessel has been tested and is rated as suitable for use at the intended temperature and pressure required. If the rating is insufficient, the work must not be carried out. Users should also take care to check if any residual pressure remains in the vessel before opening it. One possible solution to this common problem can be found in the novel PressureSyn reactor, featuring a unique locking collar which can only be opened with a single key forming part of the vessel head. The vessel simply cannot be opened while any pressure remains.

- Maintenance: No matter which scientist, or team, technically owns the laboratory pressure reactor, the final responsibility for maintenance remains with whoever intends to use the apparatus. Sorry but that means you! Service records should be accessible and up to date. Users should examine the equipment themselves to look for issues such as erosion of o-rings, damage to fittings on the vessel head which could cause leakage, and obvious wear and tear. If the user has any concerns about the state of the pressure reactor, then it must not be used until a suitably qualified engineer has carried out testing and certified that it is safe to proceed.

- By-products and loss of control: Have you identified what by-products will be produced as a result of your reaction, and how they will behave? Have you considered the circumstances under which the reaction would become uncontrollable? By anticipating such issues the user can seek to avoid them, and make plans to control the situation.

- Scale-up: When working with particularly hazardous reactants, especially unfamiliar ones, , users should start with small volumes and increase only once they have established a safe path to do so. Are you 100% sure you’ve checked for any likely or possible risks for your intended process?

- External safety: Have you thought carefully about the physical location of where you’re setting up your reaction? Many pressure reactors are small enough for use on any laboratory benchtop and are, therefore, easily moved. The space should be well ventilated, and ideally close to a fume hood or exhaust fan so that any gases can be discharged safely. There should never be any naked flames in the vicinity of the pressure reactor.All Asynt pressure reactors are available with a burst disk – an integral safety feature capable of discharging unsafe pressures. However, we’d advise you to use ear protection as this discharge, should it occur, can be extremely loud. Users should note that certain explosive reactions can take place at such speed that the explosion may damage the vessel before the burst disk can release the pressure. The best protection against this is to operate your pressure reactor behind a suitable screen, or in a specialised cubicle.

- Reality check: When working with pressure, it’s best to take a moment and run a risk assessment. Whether this is required as part of your record keeping, or purely as a tool for self-preservation, it is always a good idea. Have you got all your PPE (personal protective equipment) on properly?

Let’s be honest – we all get tired, distracted, hungry (or even hangry!), and a bit caught up with our thoughts. The short period of time it would take to consider the simple steps above could make all the difference in the safe execution of your pressurised reaction.

Hopefully, you’ve found these ten simple steps for pressure safety in your laboratory useful, but if you’d like any further guidance please don’t hesitate to reach out to our experts.

You can speak with us now via the LIVE CHAT box at the bottom right of your screen, email via [email protected] or telephone +44 (0)1638 781 709. Alternatively please complete your details in the short form below.

If you’d like more information about the wide range of turnkey and bespoke pressure reactors that Asynt offers, please click to view here on our website: www.asynt.com/products/pressure-reactors/

Request more info