Impellers come in many different shapes and sizes. Trying to choose the right one for your application can be confusing so the most important know-how/expertise has been compiled here to raise awareness of the various factors that should be considered when selecting an impeller for overhead stirring.

We’ll explain the most common impeller designs, their importance, and the reasons why impeller size should be carefully considered as well as shape.

Let’s begin by considering three terms that will require understanding before we carry on…

- Flow: the rate at which your substance moves around your mixing vessel.

- Shear: the force put upon your liquid by differences in velocity, either with adjacent solid or liquid, that leads to localised deformation along the shear plane. The rate of shear is the measurement over time of this difference in velocity over distance.

[Note: Shear force leads to Shear strain (the angular deformation) leads to shear stress (the restoration force)] - Viscosity: the measurement of how thick your mixture is, or how much resistance to flow due to internal friction your mixture has.

All fluids have a resistance to flow, known as viscosity. This resistance is measured by applying shear force at variable speeds across the surface of the liquid (usually measured in centipoise ‘cps’). Commonly, you will see referenced “Newtonian” fluids, which have a constant resistance to flow across shear rates. Think water, gas, and beer. “Non-Newtonian” fluids have variable resistances to flow due to pressure or external force. For example, salt-solutions like ketchup become runnier when shaken. when it’s warm. In many liquids, viscosity can also be is altered with an increase in shear force, resulting in increased or decreased fluidity.

A key principle of the relationship between viscosity and shear rate is that they are typically inversely related. If you have increased viscosity, the shear rate is reduced. And vice-versa. You can optimize your process by balancing viscosity and shear rate, or using specific flow patterns to your advantage.

The first three things to consider when selecting an impeller are:

- What size vessel are you intending to use?

- The level of viscosity of the material you’re working with

- What your desired outcome of the application is (such as aeration or high shear?)

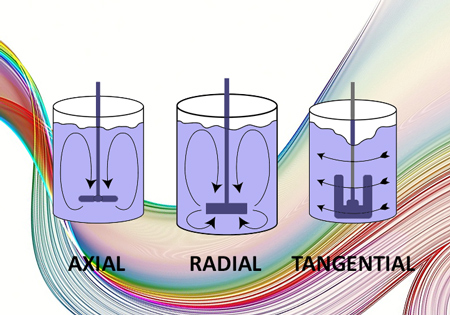

The next thing to consider is your desired flow pattern:

- Axial flow: Gives you top to bottom motion in the tank and is ideal for stratification or solid suspension. Shear tends to be lower but there’s more flow compared to radial flow.

- Radial flow: Fluid is moved sideways and then either up or down, before moving back to the center. Radial flow is suitable for high-shear applications like emulsification or liquid-gas dispersion. While shear tends to be higher, there’s less flow compared to axial flow.

- Tangential flow: Fluid is moved horizontally around the vessel as with a paddle. This is most suitable for mixing high-viscosity materials. Shear is low and there is little vertical flow.

Impeller design and their significance

|

Image |

Type | Flow | Notes |

|

Anchor | Tangential |

|

|

Pitched blade propeller | Axial |

|

|

Ring | Radial/Axial |

|

|

Radial flow | Radial |

|

|

Crossed | Radial |

|

|

Straight | Radial |

|

|

Paddle | Tangential |

|

|

Dispersion (saw tooth) | Radial |

|

|

Collapsible (centrifugal) | Radial/

Axial |

|

|

Half-moon | Axial |

|

|

Coil | Radial |

|

|

Beater paddle | Radial |

|

|

Chain paddle | Radial |

|

The Importance of Impeller Size

Once you have an impeller design selected, it’s critical to consider the diameter of it.

Impeller size is primarily restricted by the size of the vessel you’re using. Obviously, not only does the impeller need to fit inside the body of the vessel, but it also needs to fit through the opening it will be inserted into. A stirrer blade which can be tilted might be helpful.

The diameter of the propeller head is directly related to the width of your mixing vessel.

Using a “D/T ratio”, where “D” is the diameter of the mixing blade and “T” is the

width of the tank, we can compare the size of the tank to the size of the impeller.

Ideally, you would want your impeller to measure one-third of your tank’s diameter. If

that cannot be achieved exactly, it is usually recommended that you try finding a ratio between one-fifth and three-fifths.

If your ratio is less than one-fifth, your impeller is almost certainly too small for your vessel and the propeller blade won’t be able to generate enough flow to mix the ingredients effectively.

Adversely, if your ratio is more than three-fifths, the impeller is too big for your vessel. Using a propeller that is too big may create top and bottom separation in your mix, preventing movement.

The placement of the impeller blade is as critical as the aspects of the blade itself. The optimal impeller height off the tank bottom is one-third the overall height of the vessel. For example, if you had a tank that was 24 inches tall, you’d want your blade positioned at 8 inches from the bottom of the tank. If the blade gets too low, you’ll notice ingredients directly below the blade that did not get mixed well. If the blade is too high, you can create a vortex that forces the liquid below the impeller and begin mixing air into your liquids.

In some cases, using too big of an impeller can be a problem, such as when creating axial flow. If the impeller is too large, the re-circulation path will be obstructed, inhibiting proper mixing.

Below are some very general guidelines to help with impeller size, but there may be quite a bit of trial and error involved in your decision.

- Radial or axial flow: The impeller diameter should be about ⅓ of the vessel diameter (less than 70% for axial flow).

- Anchor or paddle impeller: The impeller diameter should be around 90% of the vessel diameter.

It’s worth noting here that impeller size is a big factor in scaleup. If you do intend to scale up your process, you need to avoid using a size (and shape for that matter) that can’t be mimicked in your production setting. As such, it’s a good idea to consult with production engineers early in the development process.

Different Impeller Materials

While most impellers are made from metal, these aren’t always ideal for every application. For example, when mixing certain acids or other corrosive materials, they could react with the impeller, ruining the sample and the impeller at the same time.

There are different grades of stainless steel available but a common alternative is stainless steel coated with Teflon™ (PTFE).

How can we help you?

If you’d like to talk with us about your stirring requirements, think it may be worth a second opinion perhaps on what you’re currently using, or are planning a new project – please don’t hesitate to reach out! You can find all our contact info via THIS page here on our website, talk to someone right away on our LIVE CHAT app (bottom right corner of the screen), email us on [email protected], or pick up the phone and call us on +44 (0)1638 781 709. We can’t wait to hear from you!

Further reading:

|

PTFE Accessories including stirrers, guides and reactor lids |

|

|

DrySyn Vortex – parallel overhead stirring with just one stirrer motor |

|

Static dissipative PTFE reactor accessories |

Sources: https://www.bola.de/en/technical-information/stirring-and-mixing/choice-of-stirring-elements-and-what-you-should-know-about-them/

https://stirrers.net/blogs/blog/selecting-an-impeller-for-your-overhead-stirrer