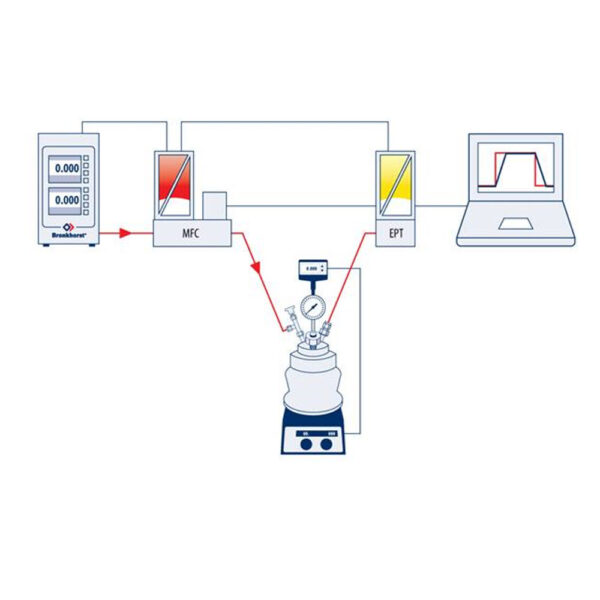

Gas Mass Flow Controllers

EL-FLOW Select F-201CV

These gas mass flow controllers & meters can be paired with your pressure reactor to allow accurate measurement and control of flow ranges between 0,16…8 mln/min and 0,5…25 ln/min at operating pressures between vacuum and 64 bar.

The mass flow controller consists of a thermal mass flow sensor, a precise control valve and a microprocessor based PC board with signal and fieldbus conversion. As a function of a setpoint value, the flow controller swiftly adjusts the desired flow rate.

Key features of these mass flow controllers include:

- High accuracy

- Fast response, excellent repeatability

- Optional Multi Fluid / Multi Range functionality

- Virtually pressure and temperature independent

- Compact design

The EL-FLOW Select series are equipped with a digital pc-board, offering high accuracy, excellent temperature stability and fast response. The main digital pc-board contains all of the general functions needed for measurement and control. In addition to the standard RS232 output the instruments also offer analog I/O.

As an option, an on-board interface can be mounted to provide CANopen®, DeviceNet™, EtherCAT®, PROFIBUS DP, PROFINET, Modbus RTU, ASCII or TCP/IP, EtherNet/IP, POWERLINK or FLOW-BUS protocols. The EL-FLOW® Select design features optional Multi Gas / Multi Range functionality, providing (OEM-) customers with optimal flexibility and process efficiency.

Other models/specifications are also available.

Talk to us today about your complete pressure reactor system requirements.

Measurement / Control System

| Flow range (intermediate ranges available) | min. 0,16…8 mln/min max. 0,5…25 ln/min (based on N2) |

|---|---|

| Accuracy (incl. linearity) (based on actual calibration) | ± 0,5 % RD plus ±0,1%FS |

| Repeatability | < 0,2 % RD |

| Turndown ratio | up to 1:187,5 (1:50 in analog mode) |

| Multi fluid capability | storage of max. 8 calibration curves; optional Multi Gas / Multi Range functionality up to 10 bar abs |

| Settling time (in control, typical) | standard: 1…2 seconds option: down to 500 msec |

| Control stability | < ± 0,1 % FS (typical for 1 ln/min N2) |

| Operating temperature | -10 … +70 °C |

| Temperature sensitivity | zero: < 0,05% FS/°C; span: < 0,05% Rd/°C |

| Pressure sensitivity | < 0,1% Rd/bar typical N2; 0,01% Rd/bar typical H2 |

| Max. Kv-value | 6,6 x 10-2 |

| Leak integrity, outboard | tested < 2 x 10-9 mbar l/s He |

| Attitude sensitivity | max. error at 90° off horizontal 0,2% at 1 bar, typical N2 |

| Warm-up time | 30 min. for optimum accuracy 2 min. for accuracy ± 2% FS |

Mechanical Parts

| Material (wetted parts) | Stainless steel 316L or comparable |

|---|---|

| Pressure rating (PN) | 64 bar abs |

| Process connections | compression type or face seal (VCR/VCO) couplings |

| Seals | standard: Viton®; options: EPDM, Kalrez® (FFKM), FDA and USP Class VI approved compounds |

| Weight | 0,6 kg |

| Ingress protection | IP40 |

Electrical Properties

| Power supply | +15 … 24 Vdc | ||||

|---|---|---|---|---|---|

| Max. power consumption |

|

||||

| Analog output | 0…5 (10) Vdc or 0 (4)…20 mA (sourcing output) | ||||

| Digital communication | standard: RS232; options: PROFIBUS DP, CANopen®, DeviceNet™, PROFINET, EtherCAT®, Modbus RTU, ASCII or TCP/IP, EtherNet/IP, POWERLINK, FLOW-BUS |

Electrical Connection

| Analog/RS232 | 9-pin D-connector (male); |

|---|---|

| PROFIBUS DP | bus: 9-pin D-connector (female); power: 9-pin D-connector (male); |

| CANopen® / DeviceNet™ | 5-pin M12-connector (male); |

| FLOW-BUS/Modbus-RTU/ASCII | RJ45 modular jack |

| Modbus TCP / EtherNet/IP / POWERLINK | 2 x RJ45 modular jack (in/out); |

| EtherCAT®/ PROFINET | 2 x RJ45 modular jack (in/out) |

UK / Europe / Global Delivery

Developed in collaboration with our clients / Bespoke design service

Committed to developing sustainable & practical improvements for scientists worldwide

Martyn Fordham, MD