What is a molten salt reactor?

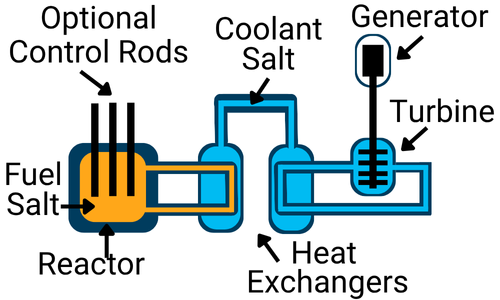

A molten salt reactor (MSR) is a nuclear reactor that uses molten salt as the primary reactor coolant. The coolant is either mixed with the molten fissile salt or surrounds the fuel rods. They have a range of benefits, including:

- The thorium they can use as fuel is significantly more abundant than uranium.

- They can ‘burn’ waste from other nuclear reactors.

- Lower operating pressure than many current reactor designs.

- Waste decays much faster than waste from those using existing technologies.

- Risk of meltdown removed when fuel is already in a molten state.

The idea of using molten salts for nuclear energy has been around since the 1950s. The original “Aircraft Reactor Experiment” at the Oak Ridge National Laboratory, in Tennessee used Inconel for the superstructure of the reactor but was never taken beyond the experimental level. It managed to run for about 100 hours at 860°C before it was shut down.

In recent years interest in MSRs has grown significantly as the need for an inexpensive, effective alternative to fossil fuels has grown in demand, and fusion technology, so far, remains out of reach.

Specifications:

One key feature of a MSR is its high operating temperature. Our latest MSR build has an operating temperature of 650 ̊ C. The temperature is significantly higher than the pressurised water reactors most commonly used for energy production.

This high operating temperature has the benefit of removing the risk of a nuclear meltdown as the fuel / salt mixture is already in a molten state.

Simplified diagram of an example MSR

Simplified diagram of an example MSR

Materials:

Molten salts can be highly corrosive, especially at high temperatures. So, lining materials for the vessel need to be thermally and chemically resistant, as well resistant to embrittlement under the intense neutron flux.

Because of this, materials are required with the inherent ability to perform under extreme conditions. This makes nickel, and alloys such as Hastelloy, ideal as they can perform under high temperatures and pressure, while maintaining resistance to corrosion and neutron irradiation.

Another material frequently used for neutron absorption (also known as neutron poisoning) is boron carbide. It is an extremely hard material with a high melting point and complex crystalline structure often used in control rods. Adapting it for use with MSRs maybe more challenging due to the reactivity, but research is this area is ongoing.

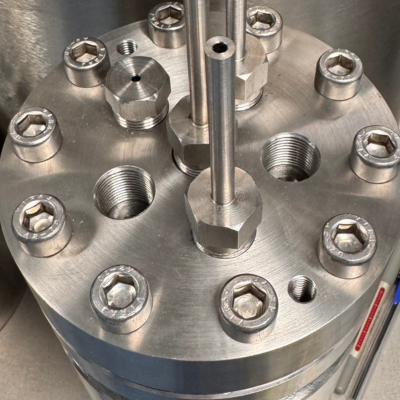

MSR Hastelloy Superstructure in construction

What is Neutron Embrittlement?

Neutron embrittlement is caused by high energy neutrons moving atoms on a microscopic scale, altering the structure of a material at the atomic level and causing the material to become brittle.

Challenges:

One of the largest challenges is the aforementioned corrosive nature of molten salts. Even the most resistant materials are not immune to the effects. There are a few ways in which this risk can be managed:

- Purification of the salt

- Control of redox potential

- Use of redox buffers

These techniques are all subjects of research, but if effective, molten salts will be considerably closer to industrial application.

Our most recent MSR Project has an operating pressure up to 10 barg

Future:

Molten salt reactors represent an exciting opportunity of the future of nuclear energy production. If they can be successfully developed at an industrial scale, they’ll be able to provide cheap, clean energy while removing many of the existing downsides of nuclear power, such as lingering waste and risk of accident.

Many countries have been making significant investments in this field, including the United Kingdom, but other countries such as China are leading the way at present. If we can develop an effective reactor design, we’ll be placed in excellent stead for a future of cheaper, cleaner and reliable energy.

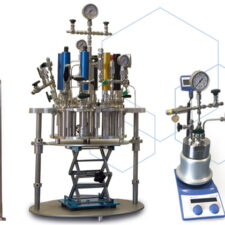

This is why we are thrilled to be playing our own small part in manufacturing pilot scale, experimental reactors, hopefully helping to pave the way towards eventual industrial application.

Beyond Nuclear:

Although the main focus around molten salt reactors in nuclear power they have also been involved in wider research, from energy storage to chemical synthesis, with the very high operating temperature potentially opening up new synthetic routes.

Conclusion:

Molten salt reactor designs are rapidly improving, with an increasing amount of investment being injected into the field. Our own designs have been developed to meet the needs of operation under extreme conditions such as high pressure, very high temperature, neutron embrittlement and corrosion.

We specialise in designing and manufacturing bespoke reactors tailored to your research needs, including very high-temperature systems like molten salt reactors. Whether you’re looking for a compact benchtop unit or a fully customised vessel rated for serious thermal performance, we can help you build a setup that delivers precision, safety and reproducibility.

If you are looking to develop your own pilot scale research in this field, don’t hesitate to get in touch! Contact us via [email protected], call 01638 781709 or send us a message via the live chat in the bottom right corner.