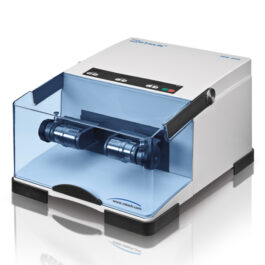

Retsch ZM 300 Ultra centrifugal mill

Rotor mills are used for high-speed size reduction of soft to medium-hard as well as temperature-sensitive or fibrous materials. The powerful Ultra Centrifugal Mill, Retsch ZM 300, provides maximum grinding performance combined with ease of use. The variable speed from 6,000 to 23,000 rpm allows for gentle, neutral-to-analysis sample preparation in a very short time.

Thanks to an integrated temperature monitoring system, reproducibility is guaranteed even for long grinding processes or pulverization of large sample volumes.

The wide selection of rotors, ring sieves and cassettes available makes the Retsch ZM 300 a versatile piece of lab equipment which meets the requirements of a great variety of size reduction tasks.

The ZM 300 is easy and safe to operate. The large touch display with rotary knob permits convenient entry of the grinding parameters. It shows the current cassette temperature and load during grinding which helps to prevent overloads by feeding the sample too quickly.

A push-fit system without screws and the patented cassette principle allow for easy insertion and removal without tools.

As a result, cleaning rotors and ring sieves is particularly quick and easy. All parts in contact with the sample can be cleaned under running water or in the dishwasher.

- Gentle high-speed pulverization due to pre- and fine grinding in one working run

- Optimum process control and reproducibility based on monitoring of the cassette temperature

- Patented cassette system for maximum sample recovery and easy cleaning

- Optional cassette for sample volumes up to 600 ml

- Wide speed range from 6,000 to 23,000 rpm

- Defined final fineness due to ring sieves with aperture sizes from 0.08 – 10 mm

- Collecting vessels for sample volumes from 250 ml to 4.5 l

- Automated vibratory feeder and various cyclone systems available

The maximum speed of classic centrifugal mills, like the widely used ZM 200, is usually limited to 18,000 rpm (rotor peripheral speed 98 m/s). The ZM 300 achieves a maximum speed of 23,000 rpm (rotor peripheral speed 118 m/s) and produces particles which are 15 to 20 % finer in comparison, depending on the material.

The higher speed has a particularly positive impact on the grind sizes of polymer samples which are pulverized cryogenically, or of fibrous materials like hay. Compared to models with a maximum speed of 18,000 rpm, the throughput may be increased by 10 to 15 %.

Application examples:

Grind sizes of plastic materials (POM or PP) after grinding with different sieves and speeds. The speed of 23,000 rpm results in a higher fineness for all sieves compared to grinding at 18,000 rpm. For example, a 19 % reduction in fineness can be achieved when POM is ground with a 0.12 mm distance sieve at 23,000 rpm.

The maximum sample throughput, e.g. when crushing chicken feed with a 0.5 mm ring sieve, could be increased by 16% when crushing at maximum speed of 23,000 min-1 instead of 18,000 min-1.

UK / Europe / Global Delivery

Developed in collaboration with our clients / Bespoke design service

Committed to developing sustainable & practical improvements for scientists worldwide

Martyn Fordham, MD